Brushless DC Centrifugal pump is a 12v or 24v miniature bldc motor driven DC Centrifugal water pump. It uses the principle of permanent magnet brushless DC motor, adds an impeller to its rotor, and is designed on the shell structure to make the liquid perform centrifugal motion. , Because there is no carbon brush friction, there will be no sparks, and it is used for fluid booster, cooling, and circulation systems.bldc water pump also named magnetic drive dc pump

TOPSFLO brushless DC Centrifugal pump has the advantages of high quality, good batch consistency, ultra-quiet, small size, high efficiency, low power consumption and long life.

Brushless DC water pump is a 12v 24v mini water pump, which is widely used. Function can be customized.

Plastic material imported from Japan, resistant to high temperature of 200°C

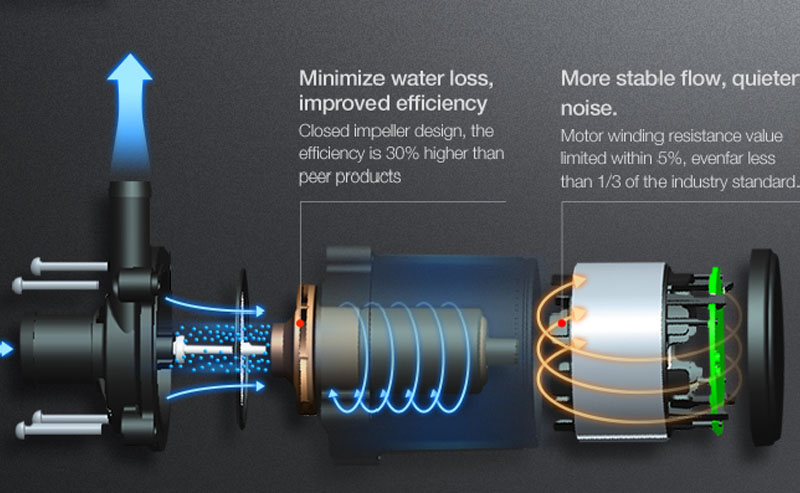

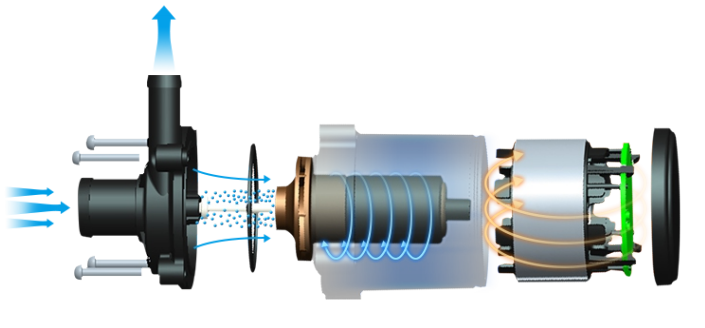

Adopt high-efficiency motor and rotor design, small water loss, large flow head and higher energy efficiency

Brushless DC Pump Series by TOPSFLO

Voltage 24V

Max Flow 42L/min

Max Water Head 30M

Voltage 12V 24V

Max Flow 9L 12L/min

Max Water Head 5M 8M

Voltage 24V

Max Flow 35L/min

Max Water Head 21M

Voltage 24V

Max Flow 35L/min

Max Water Head 21M

Voltage 24V

Max Flow 11L/min

Max Water Head 12M

Voltage 12V

Max Flow 23L/min

Max Water Head 4M

Voltage 12V 24V

Max Flow 9L 12L/min

Max Water Head 5M 8M

Volatge 12V 24V

Max Flow 17L 24L/min

Max Water Head 6M 11M

Rated Voltage 24V

Max Flow 7L/min

Max Water Head 3M

Voltage 24V

Max Flow 24L/min

Max Water Head 10M

Rated Voltage 12V,24V

Max Flow 6L/min 7L/min

Max Water Head 2M 3M

Voltage 12V

Max Flow 12.6L/min

Max Water Head 3.2M

1.What Are the Common Faults of 12V 24V DC Water Pump and How to Repair?

2.How to install a micro dc water Pump?

3.What are the features of DC water pumps and AC water pumps?

4.What is a brushless DC mini water pump?

5.7 matters needing attention in the use of brushless DC mini water pumps

6.How to Choose a High-quality Miniature Brushless DC Water Pump Supplier?

7.What are the working principle and structural characteristics of brushless DC water pumps?

8.What should pay attention to when using brushless DC water pumps?

12V 24V DC water pumps are essential components in various applications, from automotive systems to water circulation in industrial equipment. However, like all mechanical devices, they can encounter issues that affect their performance over time. To avoid operational disruptions and potential economic losses, it’s essential for operators to become adept at diagnosing and addressing common pump problems. Here’s a comprehensive guide to understanding common problems and how to address them:

Causes: Insufficient water in the pump chamber, leaks in the suction pipe or pump head, low speed leading to excessive mechanical seal leakage.

Solutions: Fill the pump chamber with water, fix air leaks, inspect and repair pipe connections, increase voltage to raise speed, and replace the mechanical seal.

Causes: Blockages in the impeller flow channel or suction pipe, severe impeller wear, insufficient power resulting in low speed.

Solutions: Remove obstructions, replace the impeller, and adjust the speed to the rated level.

Causes: Blocked inlet or outlet, insufficient cooling, or motor issues.

Solutions: Clear any obstructions, improve cooling, or check and replace faulty components.

Cause: Unstable installation support or worn 12v dc water pump bearings, poor rotor dynamic balance, eccentric bearing.

Solutions: Adjust support feet, replace bearings, and correct alignment.

Causes: Loose nut connecting the mini water pump head and body, damaged sealing ring leading to mechanical seal damage.

Solution: Tighten the nut and replace the mechanical seal.

Causes: Overly tight packing or debris jamming the impeller and mini water pump body, debris blocking the pump shaft or bearing, severely bent pump shaft.

Solutions: Disassemble the pump body to remove debris or rust, correct or replace the pump shaft.

Causes: Blocked inlet or pipeline, loose pump shaft, falling water level at the inlet, suction of the inlet hose.

Solutions: Clear blockages, clean the water diversion pipe, reinforce the impeller, adjust installation position of 12V 24V dc water pump or wait for the water level to rise.

Causes: Low power machine speed leading to slow 12v warter pump rotation, inadequate pump head, partially blocked pipeline or impeller, or impeller damage, minor water outlet pipe leakage.

Solutions: Restore the rated speed, seal any leaks, remove blockages, replace the impeller, or address minor leaks.

Cause: Accumulation of debris in the filter screen or bell mouth, lowering of the inlet water level.

Solutions: Remove debris and increase the inlet depth.

Regular maintenance and prompt problem-solving will help ensure the longevity and efficiency of your 12V 24V DC water pump, allowing it to continue serving your needs effectively. By understanding these common faults and knowing how to diagnose and repair them, you can extend the lifespan of your pumps, reduce downtime, and ensure consistent functionality. Remember that safety precautions should always be observed when handling and maintaining water pumps.

Installing a micro DC water pump is a straightforward process when you follow the right steps. These compact pumps are essential components in various applications, including cooling systems, medical devices, and more. In this guide, we’ll walk you through the process of correctly installing a micro DC water pump.

Step 1: Gather Your Tools and Materials

Before you begin, make sure you have all the necessary tools and materials. You’ll typically need:

Micro DC water pump

Mounting brackets or hardware

Hoses or tubing

Hose clamps

Electrical connectors

Screwdriver or wrench

Voltage source (battery or power supply)

Step 2: Choose the Installation Location

Select a suitable location for your micro DC water pump. Consider factors like accessibility, proximity to the fluid source, and ventilation.

Ensure the chosen location allows for proper pump mounting and connection to the fluid system.

Step 3: Mount the Pump

Use the provided mounting brackets or hardware to secure the pump in its designated location. Ensure the pump is securely fastened to prevent vibration during operation.

Step 4: Connect the Inlet and Outlet

Attach hoses or tubing to the pump’s inlet and outlet ports. Use appropriate fittings and hose clamps to create a secure and leak-free connection. Double-check that the connections are tight and properly sealed.

Step 5: Electrical Wiring

Follow the manufacturer’s wiring instructions to connect the pump to the appropriate power source. Ensure you use the correct voltage and observe polarity. Use suitable wire gauges and connectors to minimize voltage drops and ensure efficient operation.

Step 6: Prime the Pump

Before starting the pump, prime it by filling the inlet and outlet lines with the fluid. This prevents dry running, which can damage the pump.

Allow the pump to fill completely with fluid to ensure proper priming.

Step 7: Ventilation and Monitoring

Ensure proper ventilation in the installation area to allow any trapped air to escape from the system. Monitor the system during operation to check for any air pockets that could affect pump performance.

Step 8: Temperature Control

Keep an eye on the pump’s operating temperature. Overheating can lead to reduced efficiency and potential damage. Implement cooling solutions like heat sinks or fans if needed.

Step 9: Safety Measures

Follow safety guidelines and regulations during installation and operation to protect personnel and equipment. Consider implementing emergency shut-off mechanisms in case of unexpected issues.

Step 10: Testing and Maintenance

After installation, thoroughly test the pump to verify its performance. Monitor for any potential issues.

Establish a maintenance schedule to ensure the pump continues to operate efficiently.

In conclusion, the correct installation of a micro 12v DC water pump is crucial for its efficient and reliable operation. By following these steps and the manufacturer’s guidelines, you can confidently install your pump and enjoy its benefits in various applications. Proper installation and maintenance will help maximize the pump’s lifespan and performance.

AC Water Pump Features

AC water pumps, driven by alternating current (AC) power, are typically operated using AC motors with voltages exceeding 36V.

Advantages:

Ease of Operation: AC water pumps rely on the 50Hz frequency of mains power for commutation, ensuring straightforward usage. A plethora of manufacturers supply AC pumps, contributing to affordability.

Disadvantages:

1.Limited Safety: AC pumps utilize voltages above 220V, surpassing the safe threshold of 36V for human contact. This necessitates stringent insulation to avert potential electric shock hazards in case of line damage.

2.Short Lifespan: AC pump motors frequently employ copper-clad aluminum wire cores, leading to elevated temperatures (approximately 120°C) and a reduced lifespan. Furthermore, they tend to consume more power compared to their DC counterparts of similar specifications.

3.High Noise: Outdated motor technology and inexpensive materials used in AC pumps lead to higher noise levels, often exceeding 40db(A). Noise tends to amplify over time with prolonged use.

4.Inconsistent Quality: Market offerings of AC pumps vary significantly in quality, and parameters may not always be accurate. Users may experience inadequate or excessive performance during pump operation.

DC Water Pump Features

DC water pumps operate using direct current (DC) power sources and are usually driven by DC motors with voltages below 36V. These can be categorized into brushed DC water pumps and brushless DC water pumps, based on the motor type used.

Advantages:

Enhanced Safety: Widely adopted brushless DC water pumps maintain operating voltages (3.5V~24V) below the safety threshold of 36V for human safety. This substantial reduction in voltage significantly reduces the risk of electric shock incidents. In regions with erratic voltage, stability is ensured through power adapters (transformers) that provide consistent power and the option to rely on batteries during power outages.

Extended Lifespan: Employing advanced brushless DC technology and contemporary design processes, these pumps boast a lifespan exceeding 20,000 hours. Operating temperatures remain low and consistent over extended periods.

Reduced Noise: Incorporating innovative shock-absorption and noise-reduction designs, DC water pumps maintain noise levels below 40db, even with prolonged usage.

Enhanced Efficiency: Brushless DC pumps rectify the issues of low energy efficiency, bulkiness, and noise associated with AC pumps. Generally, DC pumps of equivalent size exhibit 2-3 times the efficiency of AC pumps.

Intelligent Control: Unlike AC pumps, brushless DC pumps can be integrated with custom control functions, including speed regulation, temperature differential control, reverse voltage protection, dry-run protection, over-current protection, and over-voltage protection.

Disadvantages:

Brush Wear in Brushed DC Pumps: The brushed DC water pumps are prone to wear in their carbon brushes with continuous operation, leading to increased noise levels and potential commutation issues over time.

Brushless DC Water Pump Solution

After 18 years of dedicated research, Topsflo has developed micro brushless DC water pumps that address challenges encountered in AC pumps and brushed DC pumps. These solutions incorporate a rotor composed of permanent magnet material, environment-friendly pump bodies, high-precision wear-resistant shaft sleeves, and integrated rotors to prevent wear and tear.

Topsflo’s brushless DC pumps employ imported high-temperature-resistant materials, rendering them capable of enduring high pressures and operating at elevated temperatures. Withstanding temperatures up to 125°C, these pumps are well-suited for automotive engine cooling and heat dissipation systems requiring robust heat resistance.

Backed by extensive validation and customer feedback, Topsflo’s brushless DC water pumps exhibit exceptional performance in high-temperature environments, quiet operation, extended lifespan, batch consistency, and have gained acclaim from domestic and international clients.

For those seeking micro brushless DC water pump solutions, Topsflo welcomes inquiries. Their team of engineers is committed to offering the most reliable and stable water pump solutions.

I. Definition of Micro Brushless DC Mini Water Pump

Brushless Mini DC water Pump refers to a machine that uses DC 4.5V ~ 24V to drive a brushless motor to run, and the brushless motor rotation drives the impeller to rotate, thereby increasing the pressure of the liquid to achieve the effect of transferring liquid.

The water pump is generally composed of pump body, motor stator, shaft, bearing, rotor (magnets and impellers) and so on. There are one inlet and one outlet on the pump body, water enters from the water inlet, and exits through the outlet. Any water pump that adopts this form and in small size is called brushless DC mini water pump.

With the development of all walks of life and the progress of science and technology, some customers want to make the pump smaller and lower power consumption, even portable and can be powered by DC. Therefore, miniaturization of water pumps has become an inevitable trend.

II. Principle of Micro Brushless Mini DC Water Pump

Micro brushless DC water pump adopts advanced magnetic drive technology, liquid through the permanent magnet rotor high-speed rotation, static seal design instead of traditional mechanical shaft seal. The liquid is completely isolated from the motor to avoid liquid leakage and improve product life and performance.

The water pump has a built-in frequency conversion brushless DC motor, no need for carbon brush commutation, no mechanical friction and heat generation, low power, and small temperature rise.

The brushless magnetic drive overcomes the inherent defects of the brushed motor and replaces the mechanical commutator with an electronic commutator. Therefore, the BLDC motor not only has the characteristics of good speed regulation performance of the DC motor, but also has the advantages of a simple structure of the AC motor. Reversing sparks, reliable operation and easy maintenance.There is no commutator and carbon brush wear, which reduces mechanical noise and prolongs the service life of the water pump. It is not only related to performance indicators, noise, vibration, reliability and service life, etc., but also involves the manufacturing cost of the product.

At the same time, the brushless DC motor can also accurately feed back the target number of revolutions, torque, etc. Heat generation and power consumption of the motor can be suppressed by precise control.

III. Characteristics of Brushless DC Mini Water Pump

1. No leakage. Using advanced magnetic drive technology, the stator part and rotor part of the water pump are completely isolated, statically sealed, and leak-free.

2. Long life. It can work continuously for 24 hours for a long time; the service life can reach more than 20,000 hours.

3. Low noise. One-piece injection molded silent rotor is adopted, with low rotor unbalance; imported high-precision ceramic shaft, imported materials and high-precision molds, high-precision control of component size and perfect fit, the noise is 5-10dBA lower than that of water pumps with the same parameters in the market.

4. High temperature resistance. Imported high-temperature food-grade plastic parts are used, which can withstand high temperatures of 100°C for a long time without cracking or deformation.

5. Complete certification. Topsflo pumps have passed multiple authoritative certifications such as NSF, FDA, WRAS, and meet food-grade safety requirements.

6. Customization. With strong research and development strength, water pump products can be customized according to the special needs of customers.

IV. Application range of Brushless DC Mini Water Pump

Micro brushless DC water pumps are widely used in many industries including cooling circulation system, 3D laser printer cooling, battery cooling system, hot water circulation, radiator, heater, water purifier, water dispenser, coffee machine, vending machines, water heaters, water purification humidifier, sweepers, automotive air-conditioning systems, air-conditioning drainage, automotive cooling circulation systems, cleaning equipment, computer CPU cooling circulation, bathroom equipment and many other fields.

The brushless DC pump uses a DC power supply to drive the brushless motor to run. When the brushless motor runs, it drives the impeller to run, so that the liquid in the pump generates pressure and the pressure gradually increases to achieve the function of transferring liquid.

Due to its low price, small size, high efficiency, long life, safety, and quietness, brushless dc mini water pumps are widely used as functional parts for fluid delivery in various equipment, such as water dispensers, coffee machines, electric vehicles, ,EV charger,solar water circulation system, computer water circulation heat dissipation, refrigeration, medical equipment, cooling system, bathroom products and other fields.

When using a DC mini water pump, you need to pay special attention to the following 7 major matters

1. Power supply correctly

Use a 12V or 24V DC transformer to supply power, and connect the positive and negative poles of the pump power line correctly. The red power wire of the water pump is connected to the positive pole, and the black wire is connected to the negative pole. The positive and negative poles cannot be reversed, otherwise the pump will be short-circuited and burned.

2. Operate the pump within the allowed voltage range

The water pump cannot be used with excess voltage, and the brushless DC pump should be used within the specified operating voltage range. If the water pump has an over-voltage protection function, when the voltage exceeds the range, the water pump will automatically stop and resume work after returning to the normal voltage range.

3.Strictly forbidden use non-conductive liquid with magnetic particles or impurities.

Ferromagnetic impurities and particles enter the magnetic drive and bearings, which will be adsorbed on the magnet rotor and cause blockage. Impurities and particles enter the pump body and damage the pump. Filtration measures should be taken as far as possible. When transporting media containing solid particles, it should be filtered at the water inlet of the brushless DC pump to prevent impurities from entering the pump and blocking it. Liquids with impurities or magnetically conductive particles are strictly prohibited. Flush in time after conveying the medium that is easy to crystallize or settle (fill the pump chamber with clean water after stopping the pump, and drain it after running for 1 minute), so as to protect the service life of the sliding bearing.

4. Operated at the specified temperature

The water pump should be operated at the specified temperature, and the temperature of the medium is strictly prohibited to exceed the standard, which will easily lead to demagnetization of the magnet and degradation of the performance of the control circuit. A platinum resistance temperature sensor can be installed on the outer surface of the isolation sleeve of the magnetic pump to detect the temperature rise in the ring gap area, so as to alarm or stop when the temperature exceeds the limit.

5. Strictly forbidden for the water pump to dry-running

The brushless DC mini centrifugal pump is strictly prohibited from dry-running, because there is no medium lubrication during running, and the rotor will rotate at a high speed, causing its temperature to rise to 200-300 degrees, which is easy to wear the rotor and cause the pump to be stuck. Therefore, you can customize dry running protection to protect the pump motor if there is a risk of running dry for prolonged periods of time.

6. The minimum pipe diameter is not smaller than the inlet and outlet

Ensure that the minimum pipe diameter in the pipeline is not smaller than the inner diameter of the water inlet and outlet. If it is less than that, the pressure of the water pump cannot be released normally, so that the rotor of the water pump rotates at a high speed, and the noise is large. On the one hand, it will also reduce the life of the water pump.

7. Installed below the liquid level

The brushless DC water pump is a centrifugal pump, which cannot automatically exhaust air or self-priming, and must be submerged or installed below the liquid level when in use (the liquid can flow in automatically when the pump is not working).

Miniature brushless DC pumps are widely used as fluid conveying functional components in various equipment due to their advantages of small size, high efficiency, long life, safety, and quietness. The water pump is to the machine application equipment, just like the heart is to the human body, the performance of the water pump directly affects the normal operation of the whole machine application equipment. So, how to choose a high-quality miniature brushless DC water pump supplier? Here would like to share with you some useful tips, mainly from three aspects: electronic components, rotors and batch consistency, for your reference.

Electronic Components

Presumably many purchasers of water pumps have been troubled by electronic failures and burn-in. The reason is often that there are problems with electronic components. The components of the water pump are the core part of the water pump, and high-quality water pump suppliers must use high-quality electronic components. So how to evaluate the pros and cons of suppliers’ electronic components?

1.Choose a well-known brand. The electronic components from big manufacturers and famous brands usually are implemented with higher standards, have stronger stability for long time running, and with higher efficiency, thus can avoid potential failures to a large extent, and the quality of the water pump will be significantly better than others.

2. Evaluate parameter sufficiency margin. In the stage of designing electronic solutions, engineers will calculate the corresponding parameters for different applications and leave sufficient margins, which makes the parameters more stable and the performance of components more reliable.

3.Professional analysis methods for evaluating key temperature rise indicators. The temperature rise of electronic components has a great impact on the lifetime of the pump, especially when the pump is working at high temperature. Professional water pump manufacturers have specialized analysis instruments and equipment for temperature rise analysis, thus the electronic solution design is more reliable.

TOPSFLO Solutions

More than 90% of the electronic components of TOPSFLO micro pumps are from international first-line brands, and 100% of the original imported materials can be traced. All components must pass six 100% full inspection processes to ensure their reliability and effectively prevent electronic failures. At the same time, the electronic solutions designed by professional electronic engineers with rich design experience in the automotive industry have sufficient margins, better heat dissipation, lower temperature rise, and higher reliability.

Rotor

After the pump has been used for a period of time, the pump chamber cracks and leaks. Why this happens? Maybe there is a problem with the rotor. When choosing a pump supplier, the quality of the rotor is usually judged by the following three points:

1.Rotor balance. The unbalanced rotor is one of the main reasons for the high noise of the pump, which directly affects the working performance and lifetime of the pump. The high-quality pump supplier uses the one-piece injection-molded magnetic silent rotor, which is molded at one time, with low rotor unbalance, high precision, no yaw, and no pump wear.

2.Processing Equipment. To produce high-precision rotors, the water pump supplier should be equipped with a series of advanced processing equipment, such as ultrasonic welding machines, which can ensure the seamless and super-strong combination of the impeller and the rotor; the roundness meter and the roughness meter to ensure the high precision of each rotor , to ensure low noise and high batch consistency, etc.

3.Experimental development equipment. High-quality pump suppliers should also have independent research and development capabilities, professional laboratories, and test conditions that are higher than industry standards, so that products can have more stable and reliable laboratory simulation analysis and testing from the research and development stage. The development failure caused by the inability of professional means to conduct professional analysis can be avoided.

TOPSFLO Solutions

TOPSFLO miniature brushless DC water pump uses an injection-molded magnetic rotor imported from Japan, which is molded at one time and has a low rotor unbalance. At the same time, the injection mold designed and manufactured by a Japanese-owned company has a precision three times higher than that of its counterparts, and with stable precision control for long-term production. On the other hand, TOPSFLO has four laboratories that meet the standards of CNAS national laboratory accreditation, equipped with international advanced testing equipment, and conducts product testing, verification, simulation analysis etc. that are stricter than the industry standards, which truly guarantees the success and reliability of the official development of the pump.

Batch consistency

The headache of many pump buyers now is that they may buy some samples in good condition, but when purchasing in bulk, there is always the problem of unstable performance, especially the noise of some pumps is higher and others are lower. And sometimes pump buyers will face with different failures, these all bring a lot of trouble to the later stage. So, what kind of pump supplier can achieve good batch consistency? The following 4 points are very important:

1.Production equipment: try to choose a pump supplier that has a complete production process, advanced intelligent production lines, and implements refined, visual and intelligent management and control of the entire manufacturing process. Advanced production equipment such as: automatic winding machine, automatic screw machine, imported servo press, ultrasonic welding machine, etc.

2.Noise laboratory: high noise and noise consistency are the big problems faced by many pump buyers when purchasing pumps. When examining the pump supplier, try to choose a supplier with a noise laboratory, which can eliminate the interference caused by external noise, ensure that the experimental results are objective and correct, and ensure the batch consistency of noise.

3. CPK process capability index: CPK is the ability of the process to ensure quality, which can directly reflect the level of batch pass rate. The larger the CPK value, the more sufficient the ability of the production process to maintain stability. When choosing a pump supplier, you should try to choose the one with the largest CPK value to ensure that each process is 100% tested, such as air tightness test, rotor test, water test and so on.

4.Noise realization means and evaluation ability: The level of noise is an important factor to measure the quality of a pump. To achieve low noise, the water pump should use a one-piece injection-molded magnetic silent rotor, which is molded at one time. At the same time, a good pump supplier should have excellent noise evaluation ability, and can conduct reliable and effective evaluations from the aspects of mold accuracy, whether the noise level is stable during long-term testing, and the noise consistency of products in the same batch.

TOPSFLO Solutions

In order to ensure the batch consistency of products, TOPSFLO only selects well-known suppliers for key raw materials of water pumps to ensure the batch consistency of different batches of materials; secondly, automation equipment is introduced from Japan, the United States, Germany and other countries to build intelligent production lines and processes batch consistency is highly efficient and guaranteed; thirdly, TOPSFLO adopts 6 full testing processes that are stricter than national standards, and is strictly controlled in accordance with the TÜV Rheinland IATF 16949 quality system standard to pursue “zero defect” quality.

Here above are the tips about the selection of water pump suppliers for your reference, hope they will be helpful to you. For more knowledge about the selection skills of miniature brushless DC water pump suppliers, please feel free to contact us.

Brushless centrifugal pump is the most widely used category in the pump applications, due to its obvious advantages in high water resistance, high efficiency, long life, low noise and vibration, compact size and so on.

So, do you know how a brushless centrifugal pump works?

How to choose a brushless centrifugal pump to match the equipment?

This article will show you details.

Brushless centrifugal pump working principle

The brushless DC centrifugal pump is driven by a brushless DC motor, and uses the rotation of the impeller to make the centrifugal motion of the water to work.

Before the pump is started, the pump body and suction pipe must be filled with water (without self-priming function), and then the motor is started to drive the impeller and water to rotate at a high speed. The flow channel flows into the pressurized water line of the pump. At the center of the pump impeller, since the water is thrown out under the action of centrifugal force, a vacuum is formed, and the water in the suction pool is pressed into the pump casing under the action of atmospheric pressure, and the impeller rotates continuously, so that the water is in the impeller. Under the action of continuous inflow and outflow, the purpose of transporting water is achieved.

Structure Features of Brushless Centrifugal Pump

Brushless DC centrifugal pump is composed of many components, including pump head, motor stator, shaft, bearing, rotor, impeller and so on.

According to the different performance characteristics of each component, the water pump presents the following structural characteristics:

1.The use of electronic components for commutation does not require the use of carbon brushes for commutation. The magnetic drive of the motor has no mechanical friction and low heat generation. Most low-power pumps can work continuously for 24 hours for a long time, avoiding the traditional brushed motor that cannot be used for a long time, spark generation and current interference during work and operation.

2.After the power is energized, the magnetic force is generated to drive the pump to work continuously, and the service life is up to 30000 hours.

3.Adopting high-performance ceramic shaft, or wear-resistant and mute graphite bearing which is integrated with magnet through injection molding, to avoid wear while making lower noise.

4 The shaft adopts high-performance ceramic shaft with high precision and good shock resistance.

5.The stator and the rotor parts are completely isolated, and the pump shaft from the dynamic seal into a closed static seal, which completely avoids media leakage.

6.The stator and circuit board parts are sealed with epoxy resin, 100% waterproof, therefore the pump can be installed underwater and completely waterproof.

7.The rotor part adopts permanent magnet, and the water pump body adopts environmental protection material.

8.By adjusting the various required parameters by the stator windings, the pump can be operated on wide voltage .

Key points of selecting a brushless centrifugal pump

Brushless dc water pump can be widely used in water dispensers, coffee machines, electric kettles, electric vehicles, solar water circulation system, instant thermal water heaters, solar water heaters, intelligent toilets, water heating mattresses, medical beauty equipment and other fields.

When choosing a brushless centrifugal pump, please be sure to first confirm the match between the pump and the equipment.

♦ First, determine the working voltage, current, head and flow, diameter size. In general, the maximum water head is the static water head with no flow when the water is pumped to the maximum head. If you want to pump the water to a certain height and maintain a certain flow at the same time, the required water head must be higher than the specified pumping height when selecting a pump.

♦ Secondly, determine the volume and shape requirements (threaded interface, the direction and diameter size of the inlet and outlet, etc.).

♦ Thirdly, determine the working environment (temperature, medium).

♦ Fourth, determin e whether there are other special functional requirements (time control, motion control, pressure control, flow control, speed control, etc.).

Topsflo professional brushless dc circulation pump application support

Since 2005, Topsflo has been focusing on high-end micro brushless DC pump research and development and production. So far, Topsflo brushless DC pump has obtained more than 50 national patents, and products have passed CQC, CE, ROHS, REACH, FDA, WRAS and other international well-known certification. Topsflo brushless DC centrifugal pump adopts advanced magnetic drive isolation type, leading peers in high temperature resistance, silence, long life, batch consistency and other aspects

Topsflo has independent research and development, technical service team, which can provide standardized products at the same time, but also meet personalized needs. With years of experience in product customization, Topsflo can help customers make the right choice. According to different application industries, Topsflo recommends customers to use different models of micro-brushless centrifugal pumps, and provides customers with different solutions to help customers form differentiated competitiveness in the industry.

1.Dry-running is prohibited.

2.Reverse polarity is not allowed (except customized).

3.The pump if dropped or with heavy vibration do not use.

4.Liquid contain impurities or magnetic particles are not allowed.

5.Liquid temperature over 80°C is not allowed (except high temperature models).

6.Acidic or alkaline liquid is prohibited (except customized).

Recommend you also directly send and email to info@topsflo.com to get our fastest response.