Pioneer of liquid-cooled mature solutions for supercharger piles

American "T company" liquid cooling for supercharger pile solution

American "T company" is the inventor of the smallest DC fast charger for EV in the world. They need a cooling water pump for the 350KW charging pile project, which can meet the working conditions of liquid temperature of 85 °C and ambient temperature of 70 °C. The customer tested number of brushless DC water pumps in the early stage, but none of them met the requirements. Later, they chose TOPSFLO TA60, which was successfully matched! Mass production will begin in February 2021. At present, the products have been sold to 41 countries, and tens of thousands of charging piles using TOPSFLO pumps are located all over the world.

——————

More than 20 successful cases of application solutions in the charging pile industryIn 2015, TOPSFLO successfully provided 300,000 units of liquid-cooled circulating pumps to TESLA.

——————

Water pumps used by Wall Street liquid-cooled charging piles, TOPSFLO Supercharging cooling pump More lighter, more reliable, more secure,Variety of data option, strong compatibility.

• 100KW - 600KW are applicable Truly empowering "cold and fast" charging piles

• No fear of freezing temperatures-40℃ to 125℃ stable operation

• Safe enough, cold and fast is what make sense, Escort for high-efficiency liquid-cooled super charging piles

• Six types of protection-Dry-running Protection, water shortage protection, blocked-Protection, over-current protection, reverse polarity protection, over-voltage protection

• Maintenance-free, lifespan is far more than 30,000 hour

• Good batch consistency, defect rate as low as 1/100000

Meet all the liquid cooling needs of DC supercharger piles in the market,Suitable for different cooling applications such as super charging pile liquid cooling module, EV charger cables cooling, etc

• Adopt international well-known brand electronic components, lower heat generation and high reliability.

• Uniquely designed PCB board, more temperature-resistant and dissipate heat more faster.

• Electronic scheme margin design is more sufficient, and lower temperature rise.

• High-efficiency motor: DC brushless motor has high efficiency, no carbon brush, no pollution, and low power consumption

• Waterproof and dustproof: separation of water and electricity, full potting of motor stator and circuit board, complete isolation of motor and rotor

• Imported raw materials: Japan's Asahi Kasei PPE shell, imported chips, high-precision silent rotor, longer life

EV Charging Cooling Pump Series by TOPSFLO

Voltage 24V

Max Flow 42L/min

Max Water Head 30M

Voltage 24V

Max Flow 35L/min

Max Water Head 21M

Voltage 12V 24V

Max Flow 22L/min

Max Water Head 11M

Voltage 24V

Max Flow 37L/min

Max Water Head 8M

Voltage 12V 24V

Max Flow 9L 12L/min

Max Water Head 5M 8M

Voltage 12V 24V

Max Flow 34L 37L/min

Max Water Head 8M

2.Liquid Cooling is the Future Trend of EV Fast Charger Market

With the rapid development of new energy electric vehicles, the demand for capacity of power battery is increasing, and the requirements for charging time is also getting shorter and shorter. DC high-power charging has become an inevitable trend in the future development of the new energy vehicle industry.

On August 30, Sinopec’s first community super charging station in the country was completed and put into use. It can charge 24 vehicles at the same time, and can charge an ordinary family car with an endurance of about 400 kilometers in 25 minutes as fastest. Meanwhile, traditional energy companies such as BP and Shell, as well as car companies such as Li Auto Inc. And XPeng Motors, are also accelerating the deployment of super fast charging.

The slogan of “5 minutes of charging continued calling 2 hours”used to be catchy, but now the slogan of “5 minutes of charging continued driving mileage 200km”has almost become a standard of every 800V new energy vehicle, which proving that the era of ultra-fast charging has arrived.

Topsflo, the Pioneer of Liquid Cooling Mature Solutions for Super Charging Piles

In order to adapt to the ultra-fast charging era and the development of electric vehicle technology, charging pile equipment is changing with each passing day, and its technological innovation and iteration speed are even at the forefront of the development of electric vehicle technology. Among them, liquid-cooled supercharging technology is even more optimistic in the industry, and has become the development trend of a new generation of DC fast charging equipment.

At the beginning of September, thousands of liquid cooling water pumps supplied by Topsflo to American T companies were shipped out as usual. According to the representative of Topsflo, T company is a world-renowned manufacturer of DC fast charging piles for electric vehicles, and Topsflo provides liquid-cooled circulating water pumps for their 350KW super charging piles, mass production starting from February 2021. At present, the 350KW super charging piles from T company have been sold to 41 countries, and tens of thousands of super charging piles using Topsflo pumps are standing all over the world.

In fact, the founder of Topsflo, Richard Wang, has awared of the huge potential of the new energy vehicle charging pile market many years ago. Mr. Wang entered the micro pump industry since 2005, and he is one of the experts who engaged in the research and development of brushless DC pumps in China at the earliest time. Mr. Wang is also a researcher who is fully proficient in micro pumps in Europe, America and Japan. Perennial attention to the European and American markets made him aware the situation early: The US electric vehicle charging pile market, which started at the end of the 20th century, has developed steadily and received strong support from all aspects of the government. In China, although the electric vehicle industry started late, development is inevitable. Seizing the opportunity is the way to develop. Therefore, Topsflo is the first to enter the market, and it has laid out the charging pile cooling application field with an advanced vision.

In 2015, Topsflo became the pump supplier of TESLA, and has provided 250,000 liquid-cooled circulating pumps for them. On the busy streets of Wall Street, Topsflo pumps are behind the rows of charging piles. Up to now, Topsflo has successfully provided high-efficiency liquid cooling solutions for more than 20 well-known enterprises in the charging pile industry.

Topsflo Redefines Liquid Cooled Charging Pile Water Pump

As the power source of the supercharged pile cooling module, the liquid cooling water pump plays a very important role in the safety and reliability of the supercharged pile. As the pioneer of the mature solution provider for supercharged liquid cooling system, Topsflo liquid-cooled circulating water pumps are suitable for different cooling applications such as supercharged liquid-cooled cooling modules, cable liquid cooling system, etc. The high quality presented is favored by customers in the charging pile industry.

First, 100KW-600KW are applicable, which truly empowers “cool and fast” charging piles. Topsflo adopts electronic components from internationally renowned brand, with uniquely designed PCB board, sufficient margin design for electronic solutions, low temperature rise, fast heat dissipation, and remarkable cooling effect. At present, the maximum output power of supercharged piles on the market is 600KW. Over the years, Topsflo has been continuously researching and making breakthroughs to fully meet the liquid cooling needs of all supercharged piles in the market.

Second, it can meet the needs of different working conditions of super charging piles, no matter it’s freezing or high temperature. Charging piles are generally installed outdoors, thus they must be able to withstand a variety of extreme weather. Each Topsflo water pump has undergone strict high and low temperature fast switching tests of the whole machine, and has a wide temperature resistance range, which can easily meet the ambient temperature requirements of -30°C to 70°C for supercharged piles on the market.

Third, intelligent control can be realized. Intelligent interaction is one of the key selling points of super charging piles. Topsflo is committed to providing customers with liquid-cooled water pumps with strong competitiveness, supporting 5V/PWM speed regulation, FG speed signal feedback, matching with different power charging piles, realizing automatic intelligent detection function, supporting failure alarm, real-time data feedback etc.。

Fourth, the life span exceeds 30,000 hours and is maintenance-free. Charging piles arranged along expressways, highways and in remote areas require long-distance maintenance, and it is difficult for personnel to be in place in time. Therefore, the advantages of Topsflo liquid-cooled water pump, which is maintenance-free and has a lifespan much longer than that of ordinary water pumps on the market, can be fully utilized.

Fifth, multiple protections make charging more stable. TA60 has six safety protection functions, such as dry-running protection, blocked protection, overcurrent protection, polarity protection, overvoltage protection, and constant power output, escorting high-efficiency liquid-cooled super charging piles.

Everything is ready, and the first year of ultra-fast charging is finally here. Focusing on the field of micro-pumps for seventeen years, Topsflo insists on independent research and development and technological innovation, based on long-term development, and constantly develops new application fields. The era of ultra-fast charging is both an opportunity and a challenge. Topsflo will continue to improve, keep up with the times and the pace of industry development, and provide customers in the charging pile industry with higher-quality micro-pump products and efficient solutions.

Affected by the international situation, oil and energy prices raised in 2022. At the same time, China has pledged to peak carbon dioxide emissions in 2030 and strive to achieve carbon neutrality in 2060. Driven by comprehensive factors, new energy vehicles have become the mainstream of future vehicles. In view of the development of the general environment, the infrastructure supporting facilities for new energy vehicles – the charging pile market has also become the focus of major enterprises.

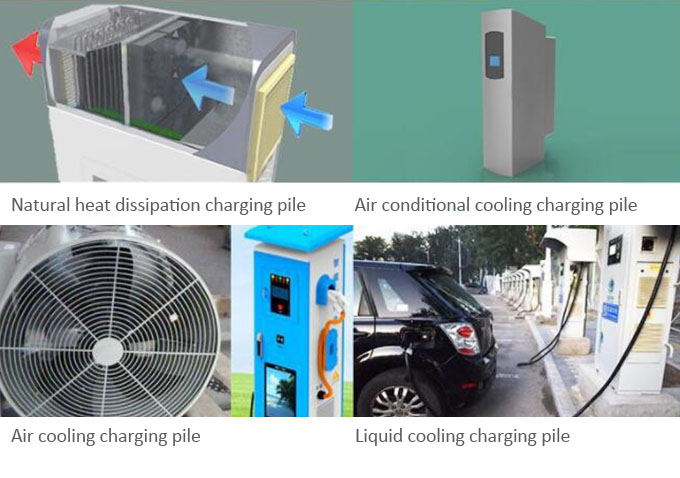

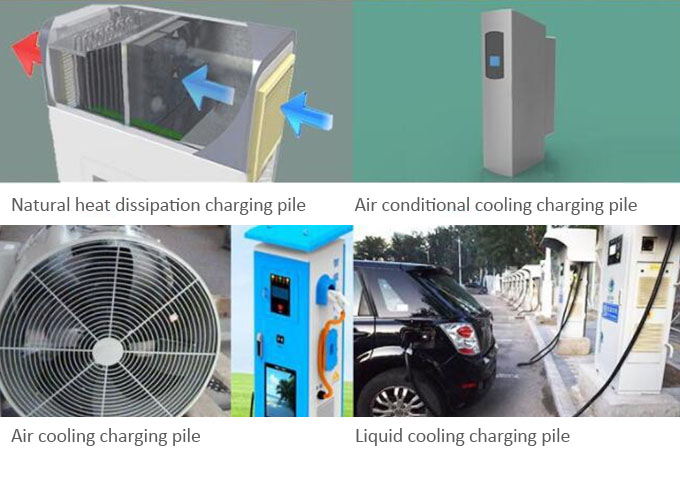

The latest data from China Economic Net on August 3, 2022: The National Energy Administration held an online press conference for the third quarter of 2022. From January to June, 1.3 million charging stations were added nationwide, 3.8 times that of the same period last year, according to the report. At present, the types of charging products on the market are mainly divided into two categories: liquid-cooled charging products and air-cooled charging products. The main difference lies in the different heat dissipation methods used by the products.

Today, editor will explore the difference and advantages and disadvantages of air cooling and liquid cooling of charging piles, so that you can avoid detours in the design of “charging pile cooling scheme”.

Heat dissipation is a difficult problem that must be solved in the construction of charging pile

Compared with other power sources, the system heat dissipation of charging pile is much larger, and the system thermal design requirements are extremely strict.

The power range of DC charging pile is 30KW, 60KW and 120KW, 350KW … 600kW etc. . The efficiency is generally about 95%, so 5% of it will be converted into heat loss, and the heat loss will be 1.5kW, 3KW and 6KW. For outdoor equipment, the heat must be discharged from the equipment, otherwise it will accelerate the aging of the equipment. At the same time, it is necessary to do a good job of waterproof and dustproof treatment to prevent the occurrence of short circuit and signal disorder of electronic equipment.

In order to intuitively let you know the calorific value generated by charging pile under normal operation, we compared the charging pile with 60KW power with the communication power supply cabinet: At present, the nominal efficiency of the mainstream module in the industry is 95%. Taking the 60KW system as an example, the heat dissipation of the module alone reaches 60*0.05*1000=3000W, which means that the heat generated by the charging pile in the charging process is 3 times of the heat dissipated by the communication outdoor cabinet under the same volume condition. It can be seen that the heat generated by the charging pile in the charging process is large, and if it is not released in time, it will cause a great safety accident. Therefore, the heat dissipation problem is one of the problems that must be solved in the promotion and construction of the charging pile system!

Air cooling and liquid cooling are the mainstream cooling methods in the market

At present, the mainstream heat dissipation methods of charging piles mainly include direct ventilation forced cooling, liquid cooling and heat dissipation by heat pipes (the whole machine is closed and air-cooled modules are used). Direct ventilation is the mainstream cooling method for domestic charging modules, but it is transforming to liquid cooling. Liquid cooling has been widely used in North American and European markets and has become the mainstream of the industry.

According to the different designs of air cooling and water cooling, the editor made a simple comparison table of advantages and disadvantages, which can compare the two types more intuitively.

| Compare Type | Air Cooling | Liquid Cooling |

| Applicable Devices | Mainly use for charging modules below 30KW | Suitable for charging modules above 30KW |

| Pros and Cons |

Low cost, easy installation, less energy consumption; high failure rate, high later operation and maintenance costs, service life of 3-5 years | Low failure rate, low operation and maintenance costs in the later period, and service life of 5-10 years |

| Air-cooled charging products that are forced to dissipate heat through external air are easily affected by salt spray and corrosive gases, and dust accumulation in the air duct will inevitably affect heat dissipation and stable operation of the module for a long time, resulting in derating or damage. Among the hardware failures of charging equipment, half of The above is the fault of the charging module. The failure rate of the charging module in some stations is as high as 10%, which is mainly caused by environmental corrosion and wet dust. | Liquid-cooling heat dissipation, adding a liquid-cooling loop to the system, the cooling unit can be separated from the module air duct, the correlation is weak, and it is not necessary to follow the installation position of the module, which provides higher protection and helps reduce the risk of salt spray, Economic losses caused by failures caused by environmental factors such as dust, cotton wool, and climate; at the same time, it reduces the time for regular manual maintenance and dust removal of the module, and reduces maintenance costs. |

Advantages and disadvantages of cooling methods.

From the picture, we know that the air-cooled heat dissipation is mainly forced to dissipate heat through the external air, which causes outdoor dust to easily enter the cabinet and contaminate the precision components. If the heat dissipation of the heating body is not strong, the heat is easy to accumulate in the heating body, and even if the external heat dissipation is strong, the effect will be limited. At present, some companies also use closed cold and heat isolation air duct technology to avoid the above shortcomings, and have been applied to actual charging piles.

Breaking through limitations, the overall cost of liquid cooling is lower

For charging operators, charging piles are the production tools they use to make money. In addition to operating income, product quality, service life, and after-sales maintenance costs are all important factors that affect the final revenue. The maximum economic value is excavated during the life cycle, so the one-time purchase cost is no longer the primary concern of operators, and the service life and later operation and maintenance costs have become the key aspects of comprehensive consideration for operators.

Compared with the limitations of air-cooled charging products, liquid-cooled charging products have gradually entered the stage and occupy an important position in the charging market.

So what are the characteristics of liquid cooling of charging modules that have been widely used in North American and European markets? From the perspective of the entire life cycle of the equipment, the overall cost of liquid cooling modules is undoubtedly lower. Compared with air-cooled heat dissipation, liquid-cooled heat dissipation has stronger heat dissipation capacity, higher efficiency, lower power consumption and stronger output voltage.

Heat dissipation capacity: The cooling of the module device is 10~20℃ lower than that of the forced air cooling module.

Efficiency: the highest efficiency > 96%, the overall efficiency > 93%. For example, a 30kW module is used for 300 days a year, and the utilization rate is 20% per day. Each increase of one point can save 450kWh of electricity per year and reduce operating costs (OPEX).

Power consumption: Standby power consumption is less than 10W.

Output voltage: The output voltage of the module can reach 1000V, which is more in line with the construction and layout trend of super charging.

Take the Tesla Supercharger V3’s liquid-cooled cable as an example, and its vehicle coolant pump is located at the base of the white SC gear. The appearance is basically the same as the previous generation, the only difference is that the charging cable looks thinner and achieves higher charging efficiency. The specific data are: power conversion efficiency (V3 is 96%, V2 is 92%) and more low cost. The total AC input is 438kVA, 526A, which can support a maximum output power of 250kW. Any additional power can be shared between cabinets. The site master controller is 4G LTE, which is used to detect the power consumption and billing of the car.

TOPSFLO’s high-quality liquid cooling water pump is favored by many giants

At present, liquid cooling has become the mainstream of the European and American charging markets, and domestic charging modules have also been concentrating on research and development to transform to liquid cooling. Liquid-cooled heat dissipation charging piles are bound to become the most reliable choice for new energy electric vehicle charging solutions.

In order to achieve the best cooling effect of the charging pile, the selection of high-quality liquid-cooled water pumps is also very important. TOPSFLO liquid-cooled EV chargingcoolant pump has a long life of 30,000 hours, maintenance-free, zero maintenance, and supports the working conditions of storage temperature -40~80 degrees, operating temperature -30~50 degrees, and medium temperature -30~90 degrees, so as to provide new Energy electric vehicles provide stable and reliable charging solutions. At the same time, it also has intelligent control function, which can realize 5V/PWM speed regulation, FG speed signal feedback and other functions, and can customize six protection functions of idling, water shortage, locked rotor, overcurrent, reverse connection, and overvoltage.

With stable performance and rich product selection, TOPSFLO dc supercharging cooling pump has attracted widespread attention in the charging pile industry, and has successfully reached strategic partnerships with many giant companies, such as the successful matching of TOPSFLO TL-B10 four-wire intelligent control water pump. In the projects of famous German companies and domestic listed companies, TOPSFLO TA60 intelligent control model has been used in the products of famous Australian companies and domestic famous companies. There are also a variety of cooling water pumps favored by many charging pile manufacturers. Welcome more charging pile customers to negotiate, and TOPSFLO engineers will recommend the most suitable cooling water pump solution for you.

Recommend you also directly send and email to info@topsflo.com to get our fastest response.