The automobile electric water pump is a vital component of the vehicle's engine cooling and preheating systems. Typically operating at 12V or 24V, examples include the TA50 and TA60 DC circulation pump series. These pumps use a brushless motor to drive the impeller, increasing liquid pressure and enabling the circulation of fluids like water. With the automotive industry transitioning towards green development and low-carbon solutions, new energy vehicles are becoming a key focus area, presenting immense growth opportunities. As an essential part of the cooling system, the automobile water pump holds significant potential for future development.

Electric circulation water pump vehicles are mainly used in various vehicle applications, such as cooling engines, supporting air circulation and heating systems, managing hydrogen fuel cell thermal systems, optimizing turbochargers and intake intercoolers, and providing thermal management for new energy drivetrains and power batteries. These pumps are also critical for cooling systems in cars, trucks, motorcycles, hybrid buses, station wagons, racing vehicles, campers, and new energy vehicles.

Electric Car water pump main use for car engine cooling circulation, electric vehicles Inverter cooling system, electric vehicle charging pile cooling circulaton,electric vehicles battery cooling system

Our car water pumps -45 degree celsius low temperature fast startup ,used for car engine preheating, heating systems (car auxiliary heaters, parking heaters),Electric vehicles charging pile ,E-Car charging ,EV charging cables cooling.

-45 °C extreme low temperature cold start, high-end 125 ultra-long stable operation

Highly adaptable circuit, designed for unstable automotive voltage and peak voltage

Car Water Pump Series by TOPSFLO

Voltage 12V 24V

Max Flow 34L 37L/min

Max Water Head 8M

Voltage 12V 24V

Max Flow 23L

Max Water Head 3M

Voltage 12V 24V

Max Flow 23L

Max Water Head 3M

Volatge 12V 24V

Max Flow 23L/min

Max Water Head 3M

Voltage 12V 24V

Max Flow 34L 37L/min

Max Water Head 8M

Voltage 12V 24V

Max Flow 23L

Max Water Head 3M

1.Optimized Design Alignment and Fluid Dynamics Study for Automotive Electronic Water Pumps

2.Application trend of automotive electronic water pump technology

3.A comprehensive guide to the installation and benefits of the TOPSFLO car Engine preheater pump

4.How to Choose a Car Preheater Circulation Pump Supplier

The drive system of a vehicle comprises the drive motor, motor controller, and reducer. These components generate significant heat during operation, particularly under heavy loads. If the temperature rises too high, it can negatively impact motor performance, potentially causing damage or failure. Similarly, excessive temperature in the high-speed reducer’s lubricating oil can reduce its viscosity, compromising the lubrication effect. For electric vehicles, the lithium-ion power battery also generates heat during charging and discharging, especially during fast charging or high-power discharge. If the battery temperature becomes too high or low, it can affect both its lifespan and performance, and in extreme cases, lead to spontaneous combustion. Additionally, components like chargers, inverters, and DC transformers require effective cooling. This study focuses on the cooling needs of the drive system and power battery, with an in-depth analysis of the vehicle’s electronic water pump.

Based on current research into electric vehicle cooling systems, this paper proposes the use of water cooling to regulate the temperature of the drive system and power battery. As illustrated in Figure 1, the vehicle’s cooling system is designed with one “large cycle” and two “small cycles.” In addition to the conventional water-cooling circuit that manages the temperature of the vehicle’s core components, the air-conditioning system within the passenger compartment is also integrated into the vehicle’s thermal management system. This enhances or shares the thermal load within the overall cooling cycle, ensuring efficient heat distribution and improved system performance.

The hydraulic and mechanical design of the electronic circulation water pump for vehicles closely resembles that of traditional mechanical water pumps, with the primary distinction being in the motor and its controller. Unlike mechanical pumps, the speed of the electronic water pump is decoupled from the engine’s speed and is instead controlled through precise matching control commands. Given the similar design and development processes for electronic water pumps used in both power battery cooling systems and drive system cooling systems, one of these applications can serve as the focus for research. In this case, the electronic coolant pump used in the drive system cooling is selected for analysis.

The vehicle’s electronic water pump comprises three main components: a centrifugal water pump, a brushless DC motor (BLDC motor), and a motor controller. The impeller of the water pump is integrated directly with the motor shaft, resulting in a compact design with minimal mechanical losses. The motor’s rotor drives the impeller, which draws the coolant in from a vertical direction and forces it against the inner wall of the pump’s volute. This process propels the coolant through the system, transferring both energy and fluid to the next stage in the cooling cycle.

As a key component of the automotive thermal management system, the electronic water pump plays an important role in the intelligent control of the temperature of the automotive subsystems, ensuring the safe and reliable operation of the subsystems, and reducing energy consumption. This paper introduces the basic structure, principle, advantages and disadvantages of mainstream electronic water pumps, analyzes its different application requirements in major systems such as internal combustion engines, new energy pure electric vehicle drive systems, and power battery thermal management, and analyzes the application and technology of electronic water pumps. Development trends are inferred.

Electronic water pump is a key component in the automotive cooling system. It is mainly used in the main cooling system of the internal combustion engine, the turbocharger cooling circuit and the air intake intercooling system. It is also used in the drive system of new energy vehicles and the thermal management system of the power battery. The use of intelligently controlled electronic water pumps in the above systems can enable the temperature of the cooling system to be closed-loop controlled according to real-time working conditions, and reduce energy consumption while ensuring the reliability of the cooled components.

1 The mainstream structure, principle and advantages and disadvantages of electronic water pumps

The electronic water pump is composed of three basic parts: hydraulic machinery, motor and motor controller. According to its fluid sealing structure, it is mainly divided into dry type and wet type electronic water pump. The hydraulic mechanical part and the motor part of the dry electronic water pump are separated independently and connected by a shaft. The water pump and the motor are sealed and isolated by rotating dynamic seals. The motor casing, water pump casing and motor controller casing are connected as a whole, and the motor drives The impeller of the water pump rotates. The wet electronic water pump is designed with a sealed thin-walled bushing between the rotor and the stator of the motor, and the rotor of the motor is integrated with the impeller of the water pump. When working, the rotor of the motor is immersed in the fluid medium, the magnetic field generated by the stator coil penetrates the thin-walled bushing and the magnetic field of the permanent magnet of the rotor forms a loop, driving the rotor and impeller to rotate, and the motor controller is installed next to the motor.

2. Application of electronic water pump technology in internal combustion engines

2.1 Application of internal combustion engine main cooling water pump

At present, the main cooling water pump of most internal combustion engines is a mechanical pump, which is installed at the front end of the engine. The driving force is provided, and the water pump and the crankshaft rotate synchronously according to a fixed transmission ratio. The disadvantage of this design is that the speed of the water pump can only rise and fall synchronously with the speed of the engine. When the engine needs to warm up quickly at low temperature, it does not need a large coolant flow, but the water pump cannot run at a low speed. However, when the engine is under low-speed and high-load conditions, a large flow of liquid cooling is required, and the water pump cannot run at high speed at this time. When driving at low load and high speed, the air cooling effect is good, and a large coolant flow is not required, but at this time the water pump is running at high speed. In order to ensure a reliable cooling effect under special working conditions such as low speed and heavy load, the mechanical pump must be designed with relatively high power. However, under most non-special working conditions, the pump operates with excess power, resulting in unnecessary energy consumption.

Because of these deficiencies in mechanical water pumps, electronic water pumps are gradually being applied to the main engine cooling system. The speed of the electronic coolant pump is no longer directly related to the engine. The electronic control unit (ECU) collects parameters such as engine speed, load, and water temperature through sensors, and compares them with the calibrated optimal water temperature under corresponding working conditions to control the water pump speed. Realize closed-loop control of liquid temperature. Its advantage is that it can control the operating temperature of the engine in the optimal range, thereby improving the thermal efficiency of the engine and reducing fuel consumption, while achieving rapid warm-up under low temperature conditions. The speed of the electronic water pump is independently controlled, and it does not need to run at full power when it is not the maximum cooling demand. The maximum power and average operating power of the electronic water pump are much lower than those of the mechanical water pump.

The power of the electronic water pump is mainly distributed between 50 and 600 W. For cars equipped with ordinary generators and ordinary 12 V batteries, the power consumption and current of this power section are still too large. The electric energy that drives the water pump is generated by the generator driven by the engine, and the multi-stage conversion of energy brings about a large loss of efficiency. And because the electronic water pump involves technologies in multiple fields such as electronics, software, motors, and hydraulic machinery, it is very difficult, and the failure of the water pump will also lead to serious consequences of engine damage, so its reliability is extremely high. Previously, only a few international auto parts companies had mature technologies and products. These factors made the application cost of the main cooling electronic water pump very high and it was difficult to popularize it.

As cars become more efficient at recovering energy to generate electricity during braking, the recovered electricity is most suitable for driving accessories such as water pumps. After years of research and development, some auto parts companies have also launched a series of cost-effective electronic main water pump products, which are now supporting mainstream auto manufacturers. After solving the power consumption and cost problems of the water pump, the electronic water pump for main cooling of the engine will quickly become popular due to its unique advantages.

2.2 Application of electronic water pump in turbocharger cooling circuit

Due to the high-temperature exhaust gas and high-speed rotation of the turbocharger, the temperature at the turbine end will reach above 600°C, while the working temperature of the sealing ring needs to be controlled below 230°C, and the bearing needs to be controlled below 150°C, otherwise the turbocharger will be damaged quickly , so efficient cooling is key. Turbochargers are generally designed with a liquid cooling circuit, but after the engine stops, the mechanical main water pump will also stop working. Without cooling of the circulating liquid, heat soaking will cause damage to the bearings, shafts and seals of the turbocharger. To solve this problem, a 15-30 W auxiliary electronic water pump is generally configured in the turbocharger cooling circuit to continue to provide cooling for the supercharger after the engine is shut down.

2.3 Application of electronic water pump in air intake intercooling circuit

Due to the high-temperature heat conduction at the turbine end of the turbocharger and the heat generated by the compression of the air, the temperature of the air passing through the turbocharger compressor can reach 150°C, while the temperature of the air entering the engine should generally be controlled below 50°C. Compressed air is used to cool the air, and the current mainstream technology uses liquid cooling plus air cooling to cool the intake air. In a supercharged engine equipped with a mechanical main water pump, a small electronic water pump of 30-60 W is often configured in the liquid cooling circuit of the intercooler to control the intake air temperature. The electronic water pump is used in the air intake and intercooling system, which can solve the cooling demand of the turbocharger through the layout of the pipeline. In engines using external exhaust gas recirculation (EGR) technology, the liquid cooling circuit of the EGR cooler is generally connected in parallel with the intake air intercooling circuit to achieve exhaust gas cooling.

2.4 Internal combustion engine thermal management system based on electronic water pump

After the engine uses the electronic main water pump, it can realize the shutdown cooling function. On this basis, the thermal management system is equipped with an electronically controlled valve group that can control the flow direction and flow of the cooling circuit, so as to realize the matching of the needs of each cooling circuit, and does not need to be equipped with multiple The water pump can better meet the thermal management needs of various parts of the engine. At present, General Motors has used this technology on the CSS series of new engines. However, its thermal management system and electronic water pump are designed and arranged separately and connected by pipelines. The integrated design of pump and valve can save installation pipelines, optimize layout space and reduce pipeline interfaces, which is conducive to cost reduction. It will become the development trend of engine thermal management technology in the future.

3 Application of electronic water pump technology in new energy electric vehicles

The application of electronic water pumps in electric vehicles is mainly the liquid cooling circuit of the drive system and the liquid cooling circuit of the power battery. The drive system includes a drive motor, a motor controller and a reducer. The drive motor generates a lot of heat when it is running under heavy load, and the high-power device IGBT in the motor controller will also generate a lot of heat. Excessive temperature will reduce the efficiency of the motor and electric control. drop, temperature runaway can lead to serious consequences of rapid burnout. In order to ensure good lubrication in the high-speed reducer, it is also necessary to control the temperature of the lubricating oil through the heat exchanger. Therefore, the driving system is generally designed with a liquid cooling circuit, and the temperature of the cooling liquid is generally required to be controlled within 90°C. The general power of the small electronic coolant pump used in this system is 40-60 W.

The lithium-ion power battery of an electric vehicle will generate heat during charging and discharging, especially during fast charging and high-power discharging. The discharge performance and cycle life are reduced, and thermal runaway may also cause the power battery to spontaneously ignite. Therefore, the power battery is designed with a thermal management system of liquid circulation. In the liquid circulation circuit, there is a heat exchanger for heat exchange with the air conditioning system, an electric heater for heating the liquid, and an electronic water pump to drive the liquid circulation, which can realize the power battery. The temperature of the power battery is controlled at 10-55°C, the temperature of the liquid in the battery thermal management system is generally lower than 50°C, and the power of the mini electronic water pump is generally 50-120 W.

There are also components such as chargers, inverters and DC transformers in electric vehicles, which also need to use liquid cooling systems. Due to the large difference in the control temperature range of the drive system and battery thermal management, the same cooling system cannot be used, so more than two electronic water pumps are generally used. The difference between the electronic water pump used for electric vehicles and the electronic water pump used for internal combustion engines is that the temperature of the working medium of the internal combustion engine water pump can reach 120 °C, and the ambient temperature can reach 150 °C, and its high temperature reliability requirements are extremely high. The electric vehicle water pump not only needs to work when the car is running, but also during the charging process, and its service life is required to be higher.

As a pioneering brand in Automotive water pump, TOPSFLO has led the way in providing innovative water pump solutions across various sectors, including solar energy, water heating mattresses, battery cooling, hot drink machines, and more since its founding in 2005. Our products have consistently received high praise in the market. In the automotive preheater sector, the car preheater water pump developed by TOPSFLO has been widely recognized by high-end preheater manufacturers, both domestically and internationally. TOPSFLO has also established long-term partnerships with leading domestic suppliers of military-grade preheaters.

So, which models are compatible with the TOPSFLO Vehicle heating water pump? And why should you choose TOPSFLO pumps? This article aims to clarify these points.

Car preheaters eliminate the need for warming up the garage in winter and solve the common problem of hard-to-start vehicles after they’ve been parked in freezing temperatures. Even in extreme cold of -30°C, you can start your car and drive away without issues. The preheater works by warming the engine, defrosting the windows, and heating the interior of the car. For fuel vehicles, the preheater gets its heat from burning gasoline, and it can work after the engine is off or during driving as an auxiliary heater.

So, what role does the car preheater water pump play in this system?

The preheater water pump circulates the coolant from the engine, heats it in the preheater, and then returns it to the engine. This process helps warm the engine and ensures smooth starting in low temperatures.

|

|

|

|

To install the pump, position it between the engine’s outlet and the heat exchanger of the interior heater. The water flow should follow this sequence:

Ensure that the Cold start water pump is installed lower than the preheater.

If air needs to be purged from the pump each time it starts, install the pump as shown in the figure below to assist with air removal and reduce noise during startup. If no purging is required, the pump can be installed in any position.

As a technology solutions leader in the micro pump industry, TOPSFLO has maintained the highest international standards since its inception. With years of experience in automotive preheaters, we have become a trusted partner for top-tier preheater manufacturers worldwide. Our expertise enables us to provide tailored, professional preheater water pump solutions that meet the demands of this growing industry. We look forward to continuing our collaborative efforts with preheater manufacturers to drive innovation and progress.

According to the research, the wear to the car engine caused by a cold start in a low temperature environment could be equivalent to the wear caused by the normal running for 200 kilometers, and nearly 60% of engine wear is from cold start. Under this situation, the emergence of car preheater has successfully solved this problem, and has been recognized by more and more people. So as the key component of the car preheater, car preheating circulating pump is absolutely quite important.

According to the data from CPCA, the cumulative national car sales in the first quarter of 2021 is 5.092 million, a year-on-year increase of 68.8%. The car preheater industry is ushering in a stage of rapid development, and there are more and more manufacturers of car preheating circulating pumps. However, the product quality of pumps is uneven, seriously affected the development of the car preheater industry. So how to choose a high-quality car preheating circulating pump supplier as a car preheater manufacturer? Let’s turn to the idea and thoughts shared by the Topsflo engineer who has been in deep ploughing car electronic pump industry for more than ten years.

Firstly, choose a car preheating circulating pump supplier with its own independent R&D and factory. Generally, these companies have a complete organizational structure, management, and service system. Therefore, they will have a strong guarantee on product quality, delivery time, custom development, etc.

Secondly, choose a supplier with stable cooperative relations with world-renowned car companies or key OEMs, as these well-known companies have their own strict and complete supplier review system. Therefore, these car preheater circulating pump suppliers who can be selected by major car manufacturers and could reach a long-term stable cooperative relationship with them, their comprehensive strength and product are definitely guaranteed.

Finally, choose a supplier who can provide customized services. As we all know, different vehicles and different application environments will have various requirements on pump’s material, parameters and process, so it’s quite vital to choose to pump suitable for given product. And the customized service can provide the best match for car preheaters.

In conclusion, I believe that you already have a certain understanding of how to choose a high-quality car preheater circulating pump supplier now. Only a well-chosen pump can improve the efficiency of the car preheater and help preheater to start easily in extreme environments, reducing the wear and tear. On the contrary, the use of inferior water pumps will not only fail to achieve the ideal preheating effect, but also will accelerate the wear of car engines and affect the brand power of car preheater companies.

As a leader in the domestic micro pump industry, TOPSFLO has been focused on R&D, manufacturing, and sales of micro water pumps for 16 years, and has long-term and stable cooperative relationships with many domestic and foreign car preheater manufacturers. What’s more, Topsflo is also one of the few companies in the domestic micro brushless DC pump industry that has obtained TüV Rheinland IATF 16949 & ISO 9001 certification. In addition, with high-quality products and excellent services, TOPSPLO has been always providing excellent pumps and preheater circulating pump solutions for high-standard car preheater customers, thus a high quality choice for car preheater suppliers.

The Automotive Electric Water Pump is an essential part of modern automobile cooling systems. Typically designed as a 12V or 24V electric coolant pump, products like the TA50 Automotive Water Pump and TA60 Automotive circulation Pump series are popular choices. Powered by a brushless motor, these pumps drive the impeller to circulate coolant, increasing liquid pressure to effectively dissipate heat and maintain optimal engine temperature.

New energy vehicles (NEVs) are at the forefront of the automotive industry’s green transformation, with significant potential for growth. As a critical component of the vehicle’s cooling system, the Automotive Electric Water Pump plays an integral role in this shift, offering substantial development opportunities. The performance and reliability of these electric circulating pumps are crucial for vehicle performance, prompting automakers to prioritize pumps that offer high efficiency, low energy consumption, and reliable operation.

Automotive Electric Water Pumps are increasingly used in various applications, including preheating systems, engine cooling circuits, hydrogen fuel cell thermal management, drive systems for new energy vehicles, and battery cooling for electric vehicles. They also serve in the cooling systems of motorcycles, hybrid buses, race cars, caravans, street vehicles, and more.

TOPSFLO has built strong, long-term partnerships with leading global automotive manufacturers like TESLA, KTM, BAIC, Dongfeng, and SAG. With our solid technical expertise, strict quality control, and advanced automated production capabilities, we ensure high-quality, consistent products for our clients. Our commitment to excellence has allowed us to maintain stable relationships with customers for over a decade. We invite more industry partners to contact us and explore the potential for collaboration.

–an alternative choice for Bosch PAD and 392 024 058 pumps

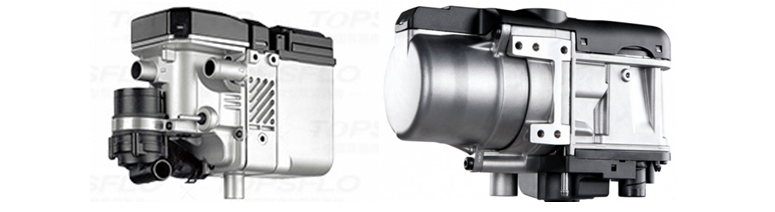

Based on original products, TOPSFLO has upgraded brushless DC car electronic water pump TA50 and TA60 series, and product raw materials, structure, quality and performance have been further improved, widely satisfied and praised by clients globally.

TOPSFLO has made the following improvements for the TA60 electric car water pump product performance improvement:

1, High efficiency ECM brushless DC motor; Durable permanent magnetic rotor & high density ceramic shaft

2, Advanced magnetic driving technology, static-seal without leakage forever

3, Replacing position sensor by micro processor position calculation, motor coreless control with much more intelligence and convenience(PWM speed control funciton available)

4, -40~125°C wide operating temperature is realized, suitable for extreme outdoor environment

5, Optimized 3 phase motor high efficiency design, combined with low-resistance copper wire, achieving large flow and low temperature rise.

6, Anti-vibration pump rubber bracket designed for automotive vibration working condition

7, Highly adaptable circuit designed specially for unstable automotive voltage and peak voltage

8, More protection functions

| Protection functions | Specific work description | |

| √ | Over-voltage protection | 24V products: when power supply voltage exceeds 28.5V, the over-voltage protection is started and voltage is retested after 5 seconds, if the voltage is < 28V, the pump will be back to work. 12V products: when power supply voltage exceeds 18.5V, the over-voltage protection is started and voltage is retested after 5 seonds, if the voltage is < 18V, the pump will be back to work. |

| √ | Over-Current Protection | When the pump operating current is > (7A for 12V products; 5A for 24V products), it’s necessary to restart pump after power failure & troubleshooting, water pump will be back to normal. |

| √ | Blocked-Protection | After pump rotor is stuck for 1 second, the pump will shut down, restart after 5 seconds, repeat the test until the pump returns to normal operation. |

| √ | Polarity Protection | Within DC 30V, if the power polarity is connected reversely, the pump will not work and unrecoverable failure will not be produced. |

| √ | constant power output | 12V products: When the voltage is > 13V, pump will be with constant power output. When the voltage increases, the product flow remains unchanged; 24V products: Whenthe voltage g> 25V,pump will be with constant power output. when the voltage increases, the product flow remains unchanged; |

| √ | Dry-running Protection | When pump runs at low speed without water, the pump will reduce the working speed.If no water is detected again,cycle running protection will be continued, and pump will be back to normal once with water. |

At present, more and more OEM customers look for TOPSFLO TA50 & TA60 to replace Bosch DC micro car circulation pump, not only because of its competitive prices, but also for its excellent performance and suitability. Specific parameters can be compared as follows:

| Comparison sheet | ||

| Specification | Bosch PAD 12V circulation pump | TOPSFLO TA50-R12-2302 |

| Rated Voltage | 12V | 12V |

| Operating range | 12-14V | 6-18V |

| Max flow rate | 23L/min | 23 L/min |

| Max head pressure | 2M | 2.5M |

| Power supply way | Battery & swiching power supply | Battery & swiching power supply/meet car power supplying way which occur high peak voltage or unstable voltage |

| Environment temperature durability | range -40-120℃ | wider range -40-135℃ / suitable for extreme outdoor environment |

| Comparison sheet | ||

| Specification | Bosch 0 392 024 058 | TOPSFLO TA60-R12-3409 |

| Rated Voltage | 12V | 12V |

| Operating range | 12-14V | 6-18V |

| Max flow rate | 38L/min | 12V 34 L/min; 24V 37L/min |

| Max head pressure | 6M | 9M |

| Power supply way | Battery & swiching power supply | Battery & swiching power supply/meet car power supplying way which occur high peak voltage or unstable voltage |

| Environment temperature durability | range -40-120℃ | wider range -40-125℃ / suitable for extreme outdoor environment |

TOPSFLO looks forward to establish cooperation with more clients. We have a strong R & D team which can achieve customized products, not only with experience and efficiency, but also giving you good satisfaction from aspects to bring a long term reliable cooperation.

Recommend you also directly send and email to info@topsflo.com to get our fastest response.